TryptaSuspension

designed by Stephen Burks

Trypta is a system of suspension lamps that offers a combination of acoustic features and lighting performance in various dimensions and colors. The cylindrical aluminum body is equipped with two LED sources to provide both direct and indirect diffused light.

Three slots along the body of the lamp permit assembly of three acoustic panels positioned at 120°. The core of the panels is made of a high-performance soundproofing material, covered with an elegant fabric offered in different colors.

The body of the lamp comes in two lengths while the panels are available in a range of different sizes, as it is possible to create varied configurations – flat, shifted and mixed – by combining panels in different measures and positions.

D97/1D

Trypta h 90

D97/1D

Trypta h 90

Main specifications

| Typology | Suspension | ||||||

|---|---|---|---|---|---|---|---|

| Application | Indoor | ||||||

| Material |

|

||||||

| Finishes |

|

||||||

| Dimensions (mm) | H min 135 max 395, W 9500, D ø 300 | ||||||

| Weight (kg) | 5.05 | ||||||

| Light Source | LED MODULE 2 x 20W dim to warm, min 1800K max 3000K, CRI 97 | ||||||

| Insulation Class | I |

D97/2D

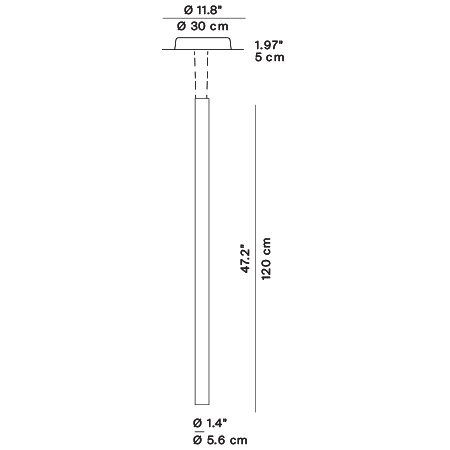

Trypta h 120

D97/2D

Trypta h 120

Main specifications

| Typology | Suspension | ||||||

|---|---|---|---|---|---|---|---|

| Application | Indoor | ||||||

| Material |

|

||||||

| Finishes |

|

||||||

| Dimensions (mm) | H min 165 max 425, W 1250, D ø 300 | ||||||

| Weight (kg) | 5.95 | ||||||

| Light Source | LED MODULE 2 x 20W dim to warm, min 1800K max 3000K, CRI 97 | ||||||

| Insulation Class | I |