StochasticSuspension

designed by Daniel Rybakken

Composed of glass spheres at different heights, Stochastic takes on infinite combinations in a sort of controlled freedom: each sphere is connected to small steel rods of different lengths that can be attached to the structure according to your own creative impulses. The light source – a double high-efficiency LED module – is enclosed in the spheres, generating warm indirect light aimed upward and downward.

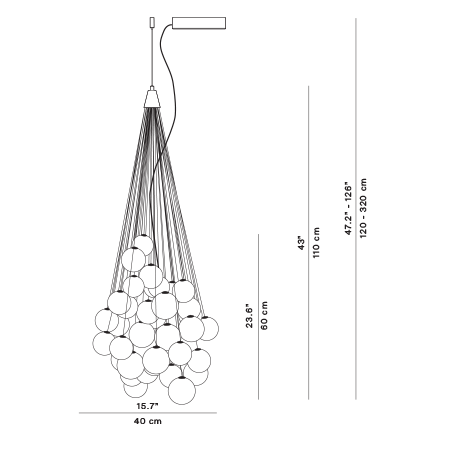

D87048

Stochastic 48

D87048

Stochastic 48

Main specifications

| Typology | Suspension | ||||

|---|---|---|---|---|---|

| Application | Indoor | ||||

| Material |

|

||||

| Finishes |

|

||||

| Dimensions (mm) | H min 1200 – max 3200, D 400, Sphere: Ø 87 | ||||

| Weight (kg) | 1.3 | ||||

| Light Source | LED 18W, 2700K, 3000K, CRI 90 | ||||

| Insulation Class | I |

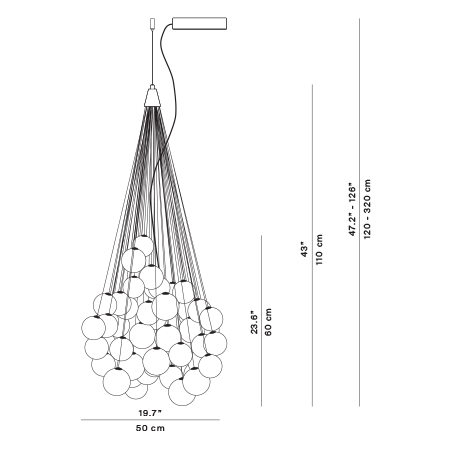

D87048 D87072

Stochastic 72

D87048 D87072

Stochastic 72

Main specifications

| Typology | Suspension | ||||

|---|---|---|---|---|---|

| Application | Indoor | ||||

| Material |

|

||||

| Finishes |

|

||||

| Dimensions (mm) | H min 1200 – max 3200, D 500, Sphere: Ø 87 | ||||

| Weight (kg) | 1.3 | ||||

| Light Source | LED 18W, 2700K, 3000K, CRI 90 | ||||

| Insulation Class | I |