Designers

Paolo Rizzatto

1/2

2/2

Paolo Rizzatto (Milan, 1941) graduated in Architecture from Milan Polytechnic in 1965. In his Milanese studio he works asa freelance in the fields of architecture, interior design and design.

In 1978 he founded the company Luceplan with Riccardo Sarfatti and Sandra Severi. He has produced designs for many Italian and foreign companies: Alias, Arteluce, Artemide, Cassina, Danese, Driade, Fiam, Flos, Guzzini, Knoll, Kartell, Laura Meroni, Lensvelt, Luceplan, Mandarina Duck, Molteni, Montina, Nemo, Philips, Poltrona Frau, Segis, Serralunga, Thonet and Veneta Cucine.

He has taught courses and given lectures at a number of universities: Columbia University in New York, Milan Polytechnic, the Cranbrook Center in Detroit, Washington University in Saint Louis, the Architecture Institute in Moscow, Palermo University and the IUAV in Venice.

His works have been published in magazines, catalogues and other publications in Italy and abroad, while his designs have been presented at seminars and exhibitions of architecture and design and are included in the permanent collections of numerous museums and foundations: the Milan Triennale, Museum of Modern Art in New York, Victoria and Albert Museum in London, Museo della Scienza e della Tecnica in Milan and Musée des Arts Décoratifs in Paris.

He has won many awards, including four Premi Compassi d’oro in 1981, 1989, 1995, 2008 and 2011 and the International Competition of Design for the “Darsena di Milano” in 2004.

Related products

Berenice Table,

Designed by Alberto Meda, Paolo Rizzatto

Berenice Wall,

Designed by Alberto Meda, Paolo Rizzatto

Berenice Floor,

Designed by Alberto Meda, Paolo Rizzatto

Costanza Floor,

Designed by Paolo Rizzatto

Costanza Suspension,

Designed by Paolo Rizzatto

Costanza Table,

Designed by Paolo Rizzatto

Costanza Wall,

Designed by Paolo Rizzatto

Costanzina Suspension,

Designed by Paolo Rizzatto

Costanzina Table,

Designed by Paolo Rizzatto

Costanzina Wall,

Designed by Paolo Rizzatto

Fortebraccio Table,

Designed by Alberto Meda, Paolo Rizzatto

Fortebraccio Spot Ceiling Wall,

Designed by Alberto Meda, Paolo Rizzatto

Grande Costanza Floor,

Designed by Paolo Rizzatto

Grande Costanza Suspension,

Designed by Paolo Rizzatto

Grande Costanza Open Air Suspension,

Designed by Paolo Rizzatto

Grande Costanza Open Air Floor,

Designed by Paolo Rizzatto

Hope Ceiling,

Designed by Francisco Gomez Paz, Paolo Rizzatto

Hope Suspension,

Designed by Francisco Gomez Paz, Paolo Rizzatto

Hope Wall,

Designed by Francisco Gomez Paz, Paolo Rizzatto

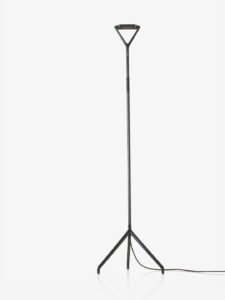

Hope Floor,

Designed by Francisco Gomez Paz, Paolo Rizzatto

Lady Costanza Floor,

Designed by Paolo Rizzatto

Lady Costanza Suspension,

Designed by Paolo Rizzatto

Lady Costanza Wall,

Designed by Paolo Rizzatto

Lola Floor,

Designed by Alberto Meda, Paolo Rizzatto

Lola Wall,

Designed by Alberto Meda, Paolo Rizzatto

Metropoli Ceiling Wall,

Designed by Alberto Meda, Paolo Rizzatto, Riccardo Sarfatti

Metropoli outdoor Ceiling Wall,

Designed by Alberto Meda, Paolo Rizzatto, Riccardo Sarfatti

Otto Watt Table,

Designed by Alberto Meda, Paolo Rizzatto

Otto Watt Wall,

Designed by Alberto Meda, Paolo Rizzatto

Queen Titania Suspension,

Designed by Alberto Meda, Paolo Rizzatto

Titania Suspension,

Designed by Alberto Meda, Paolo Rizzatto