TryptaSospensione

designed by Stephen Burks

Trypta è un sistema di lampade a sospensione che offre una combinazione di caratteristiche acustiche e prestazioni illuminotecniche in diverse dimensioni e colori. Il corpo cilindrico in alluminio è dotato di due sorgenti LED per un’emissione di luce sia diretta che indiretta e diffusa.

Il corpo della lampada è disponibile in due diverse lunghezze, mentre i pannelli sono acquistabili in un’ampia gamma di misure, con la possibilità di creare varie configurazioni, piane, sfalsate e miste, combinando pannelli di dimensioni e in posizioni differenti.

D97/1D

Trypta h 90

D97/1D

Trypta h 90

Specifiche principali

| Typology | Sospensione | ||||||

|---|---|---|---|---|---|---|---|

| Application | Interno | ||||||

| Material |

|

||||||

| Finishes |

|

||||||

| Dimensions (mm) | H min 135 max 395, W 9500, D ø 300 | ||||||

| Weight (kg) | 5.05 | ||||||

| Light Source | LED MODULE 2 x 20W dim to warm, min 1800K max 3000K, CRI 97 | ||||||

| Insulation Class | I |

D97/2D

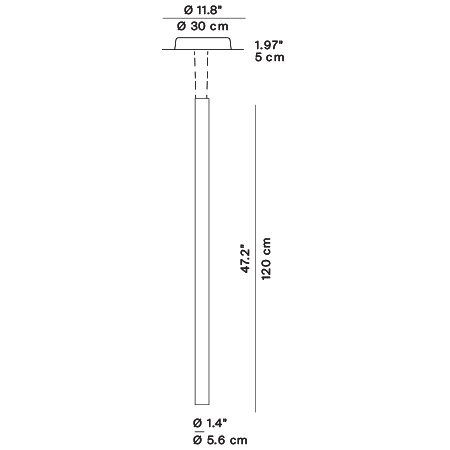

Trypta h 120

D97/2D

Trypta h 120

Specifiche principali

| Typology | Sospensione | ||||||

|---|---|---|---|---|---|---|---|

| Application | Interno | ||||||

| Material |

|

||||||

| Finishes |

|

||||||

| Dimensions (mm) | H min 165 max 425, W 1250, D ø 300 | ||||||

| Weight (kg) | 5.95 | ||||||

| Light Source | LED MODULE 2 x 20W dim to warm, min 1800K max 3000K, CRI 97 | ||||||

| Insulation Class | I |