CurlTavolo

designed by Sebastian Bergne

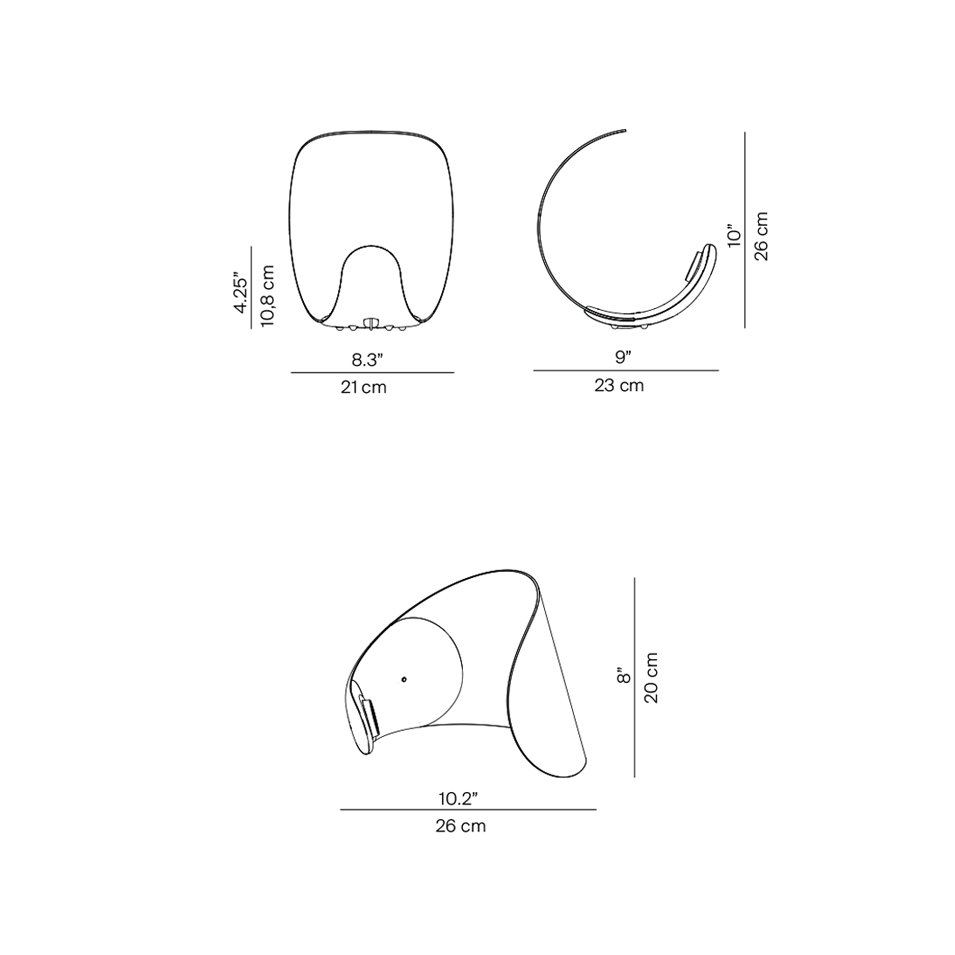

Curl è una lampada dalle dimensioni molto calibrate e con una naturale presenza scultorea. La tipologia di riferimento è la lampada da tavolino, un apparecchio al quale si chiede di fornire una luce diffusa, possibilmente schermata, e di creare un’atmosfera riposante. La forma della base consente a Curl di assumere più posizioni; al suo centro è collocato un interruttore/dimmer.

Modelli

D76N1

Curl

D76N1

Curl

Specifiche principali

| Typology | Tavolo | ||

|---|---|---|---|

| Application | Interno | ||

| Material |

|

||

| Finishes |

|

||

| Dimensions (mm) | H 260, L 210, W 230 | ||

| Weight (kg) | 0.73 | ||

| Light Source | LED 8W, 3000K, CRI 80 | ||

| Insulation Class | III |