CostanzaTavolo

designed by Paolo Rizzatto

Coniugando tradizione e tecnologia, Costanza declina il classico in forma contemporanea. Il paralume intercambiabile di policarbonato diffonde una luce calda e gradevole. Il dimmer sensoriale ad astina permette di regolare l’accensione e lo spegnimento passando per quattro livelli di intensità luminosa.

D13 D13c

Costanza stelo telescopico – dimmer

D13 D13c

Costanza stelo telescopico – dimmer

Specifiche principali

| Typology | Tavolo | ||||

|---|---|---|---|---|---|

| Application | Interno | ||||

| Material |

|

||||

| Finishes |

|

||||

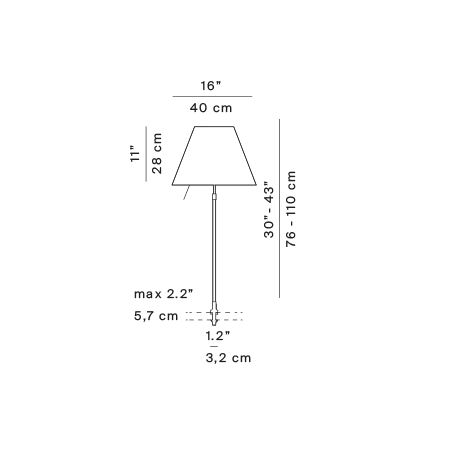

| Dimensions (mm) | H min 760 – max 1100, L base 180, W 180, D shade ø 400 | ||||

| Weight (kg) | 2.03 | ||||

| Light Source | LED E27 dimmable, HSGA max 105W E27 | ||||

| Insulation Class | II |

D13i

Costanza stelo telescopico – on/off

D13i

Costanza stelo telescopico – on/off

Specifiche principali

| Typology | Tavolo | ||||

|---|---|---|---|---|---|

| Application | Interno | ||||

| Material |

|

||||

| Finishes |

|

||||

| Dimensions (mm) | H 800, L base 180, W 180, D shade ø 400 | ||||

| Weight (kg) | 2.2 | ||||

| Light Source | LED E27, HSGA max 105W E27 | ||||

| Insulation Class | II |

D13if

Costanza stelo fisso – on/off

D13if

Costanza stelo fisso – on/off

Specifiche principali

| Typology | Tavolo | ||||

|---|---|---|---|---|---|

| Application | Interno | ||||

| Material |

|

||||

| Finishes |

|

||||

| Dimensions (mm) | H 800, L base 180, W 180, D shade ø 400 | ||||

| Weight (kg) | 1.99 | ||||

| Light Source | LED E27, HSGA max 105W E27 | ||||

| Insulation Class | II |

D13pt

Costanza perno – dimmer

D13pt

Costanza perno – dimmer

Specifiche principali

| Typology | Tavolo | ||||

|---|---|---|---|---|---|

| Application | Interno | ||||

| Material |

|

||||

| Finishes |

|

||||

| Dimensions (mm) | H min 760 – max 1100, D shade ø 400 | ||||

| Weight (kg) | 0.54 | ||||

| Light Source | LED E27 dimmable, HSGA max 105W E27 | ||||

| Insulation Class | II |

D13pti

Costanza perno – on/off

D13pti

Costanza perno – on/off

Specifiche principali

| Typology | Tavolo | ||||

|---|---|---|---|---|---|

| Application | Interno | ||||

| Material |

|

||||

| Finishes |

|

||||

| Dimensions (mm) | H min 760 – max 1100, D shade ø 400 | ||||

| Weight (kg) | 0.54 | ||||

| Light Source | LED E27, HSGA max 105W E27 | ||||

| Insulation Class | II |