CarraraTerra

designed by Alfredo Häberli

Stampata in un unico corpo di poliuretano espanso, Carrara è un Luminator scultoreo ed essenziale. Diffonde una luce indiretta comandata da un regolatore dell’intensità.

Modelli

D38L

Carrara

D38L

Carrara

Specifiche principali

| Typology | Terra | ||

|---|---|---|---|

| Application | Interno | ||

| Material |

|

||

| Finishes |

|

||

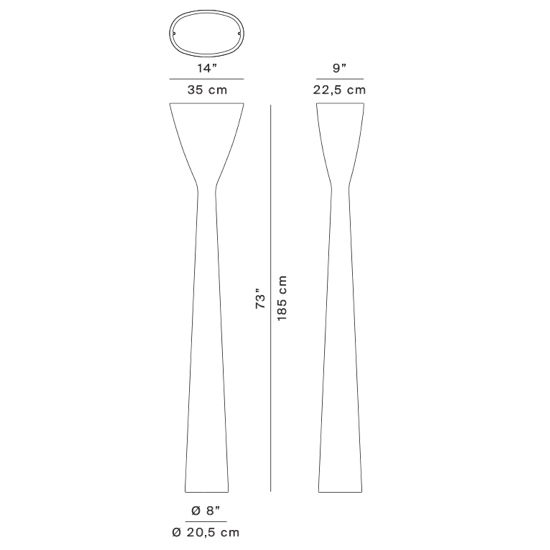

| Dimensions (mm) | H 1850, L 350, W 225 | ||

| Weight (kg) | 16.2 | ||

| Light Source | LED 45W, 3000K, CRI 80 | ||

| Insulation Class | II |