What is RoboDK?

RoboDK is a powerful and cost-effective simulator for industrial robots and robot programming.

RoboDK simulation software allows you to get the most out of your robot.

What is best about RoboDK?

-

No programming skills are required with RoboDK's intuitive interface

-

You can easily program any robot offline with just a few clicks

-

RoboDK has an extensive library with over 800 robot arms

RoboDK key benefits

The advantage of using RoboDK's simulation and offline programming tools is that it allows you to program robots outside the production environment.

With RoboDK you can program robots directly from your computer and eliminate production downtime caused by shop floor programming.

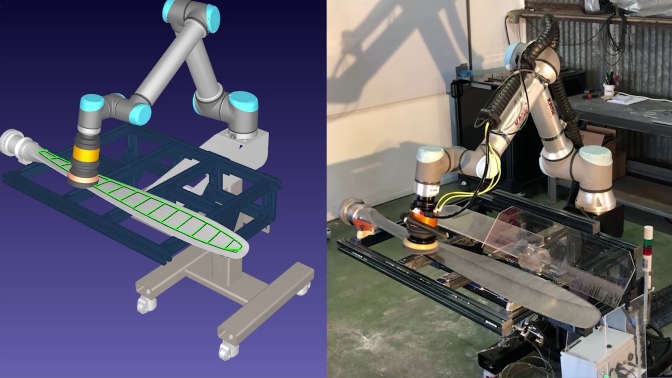

Robot Machining

Use your robot arm like a 5-axis milling machine (CNC) or a 3D printer. Simulate and convert NC programs to robot programs (G-code or APT-CLS files). RoboDK will automatically optimize the robot path, avoiding singularities, axis limits and collisions.

Send us a sample project and we will help you set it up in RoboDK!

Offline Programming Software

Simulation and Offline Programming of industrial robots has never been easier. Create your virtual environment to simulate your application in a matter of minutes.

Easily generate robot programs offline for any robot controller. You don't need to learn vendor-specific programming anymore.

Robot Library

Access an extensive library of industrial robot arms, external axes and tools from over 50 different robot manufacturers. Easily use any robot for any application, such as machining, welding, cutting, painting, inspection, deburring, and more!

Don't see your robot? Let us know and we'll include it!

Robot Accuracy

Your robot arm is not accurate enough?

Calibrate your robot arm to improve accuracy and production results. Run ISO9283 robot performance tests.

Export Programs to your Robot

RoboDK Post Processors support many robot controllers, including:

-

ABB RAPID (mod/prg)

-

Fanuc LS (LS/TP)

-

KUKA KRC/IIWA (SRC/java)

-

Motoman Inform (JBI)

-

Universal Robots (URP/script)

-

...and much more!

Proven Software Technology

From the world's largest companies

to startups.

Over 50,000 users in 50 countries

trust RoboDK Software.