J-usSuspension

designed by Alessandro Zambelli

J-us comes from an unusual interpretation of the traditional chandelier

with arms, where the technological innovation and research on materials are completely concealed from view. The warm and remarkable luminous performance and the light, dynamic design of great visual appeal give rooms a refined tone without ever overstating the image.

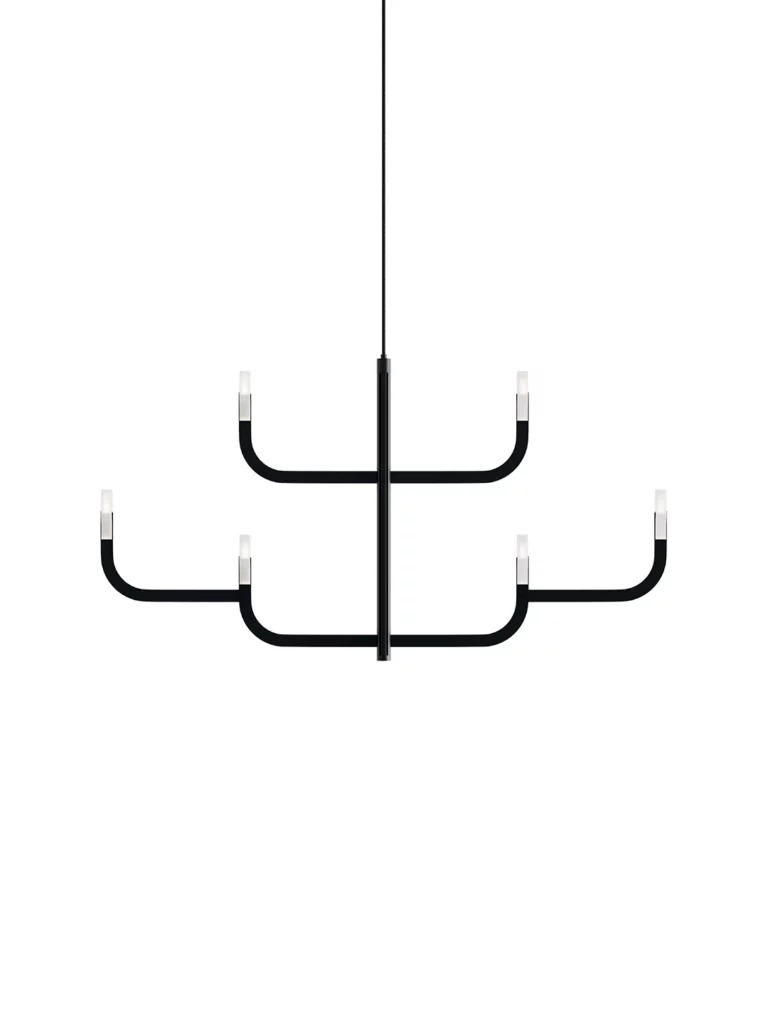

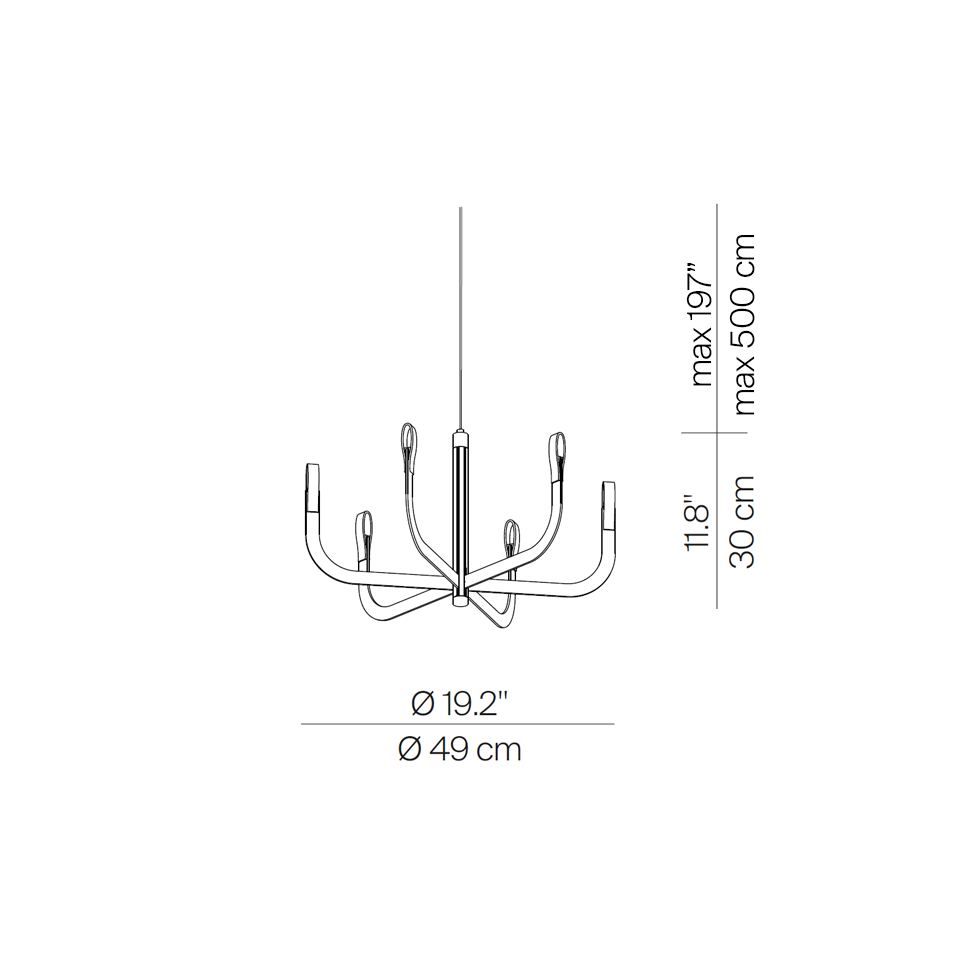

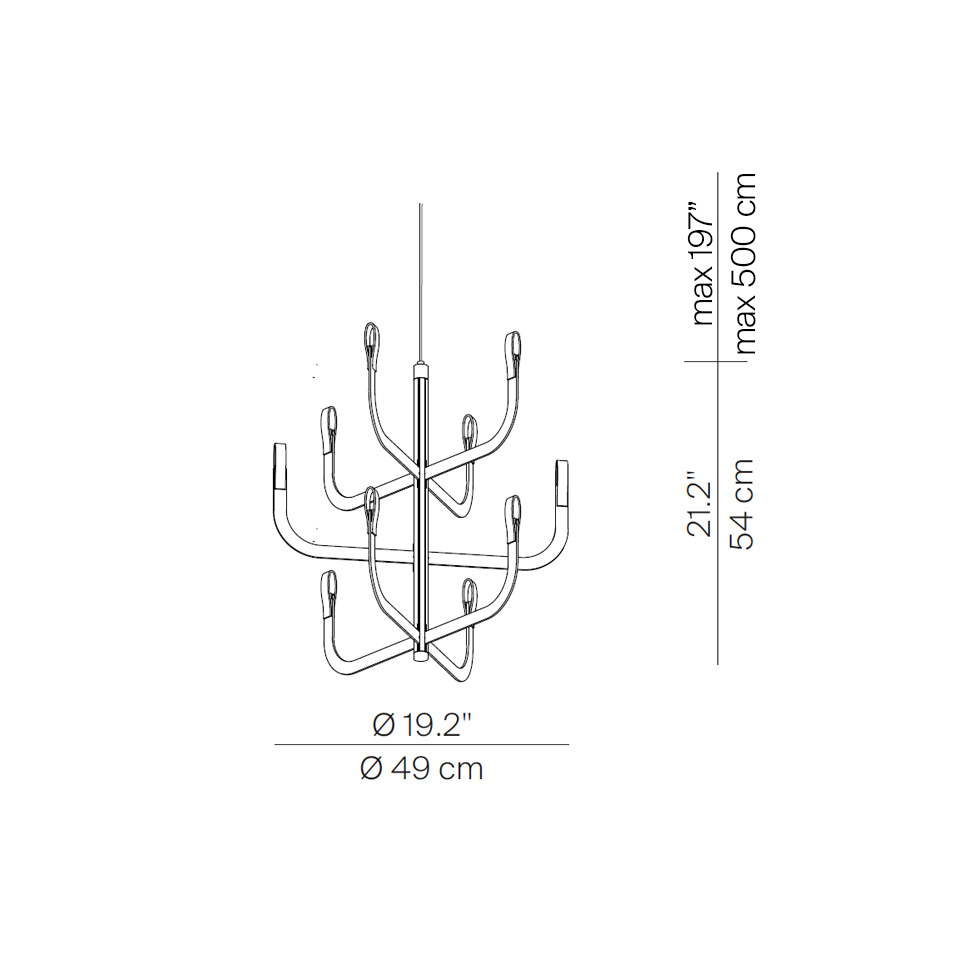

A09-A

J-us A configuration

A09-A

J-us A configuration

Main specifications

| Typology | Suspension | ||

|---|---|---|---|

| Application | Indoor | ||

| Material |

|

||

| Finishes |

|

||

| Dimensions (mm) | H body 300, cable max 5000, D ø 490 | ||

| Light Source | LED module 21W, 2700K | ||

| Insulation Class | I |

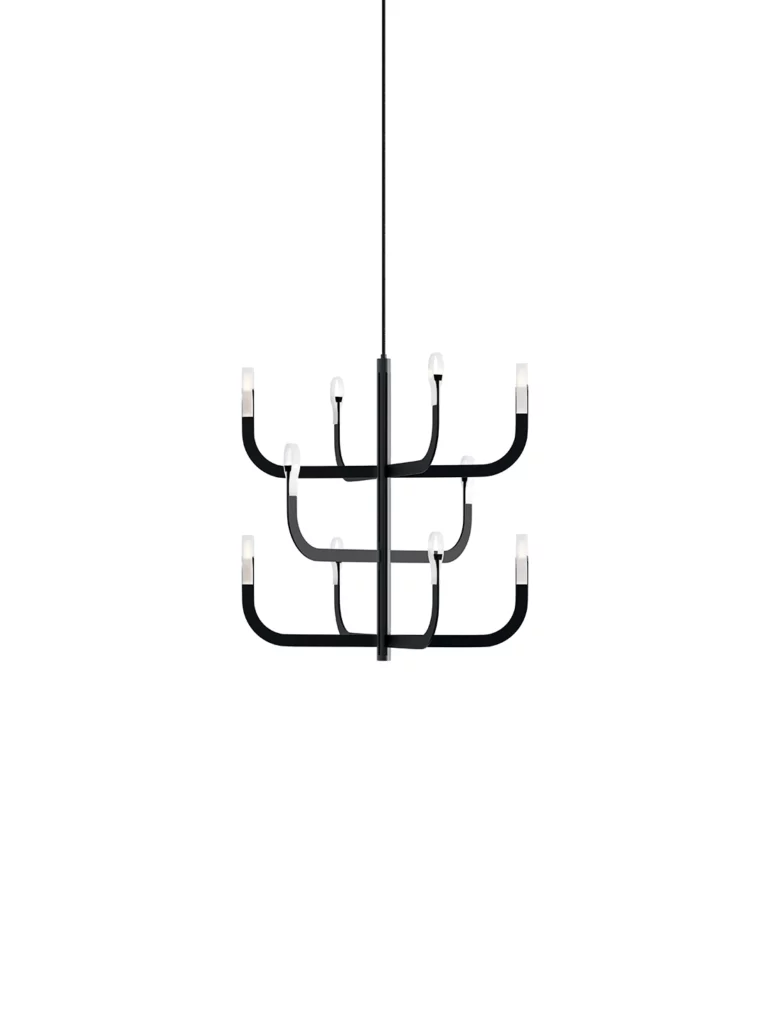

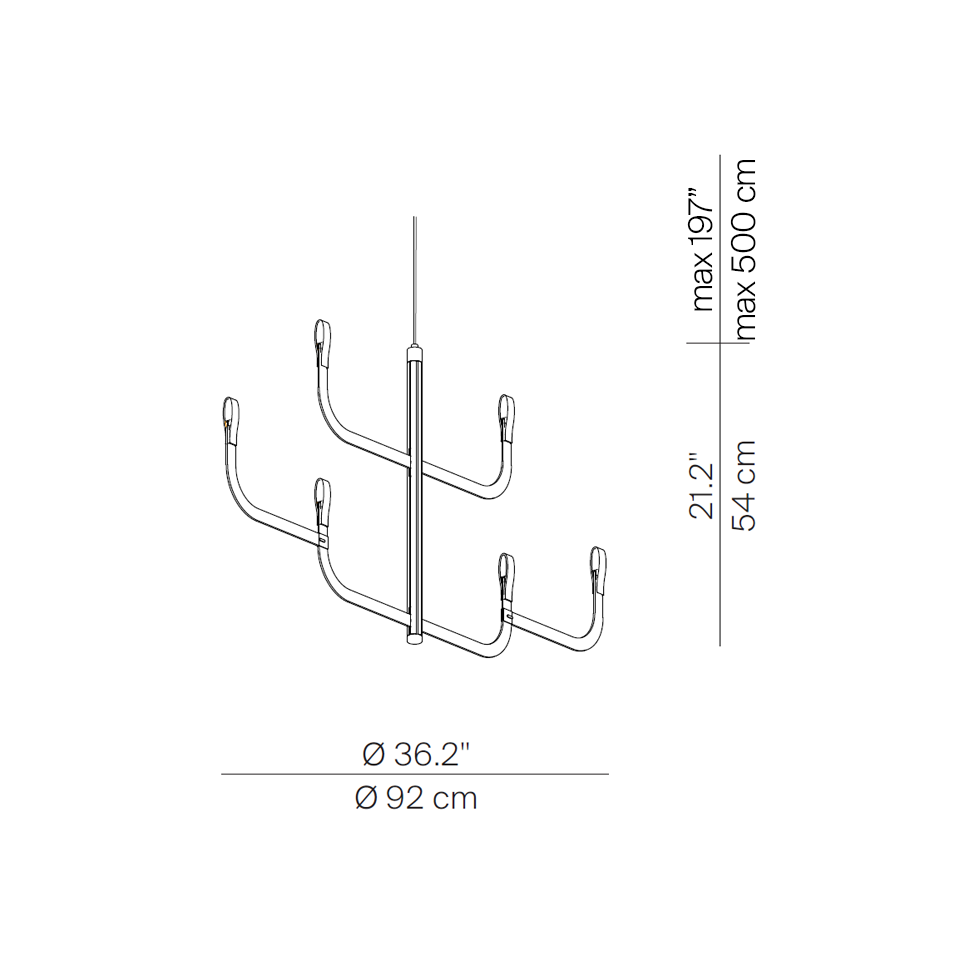

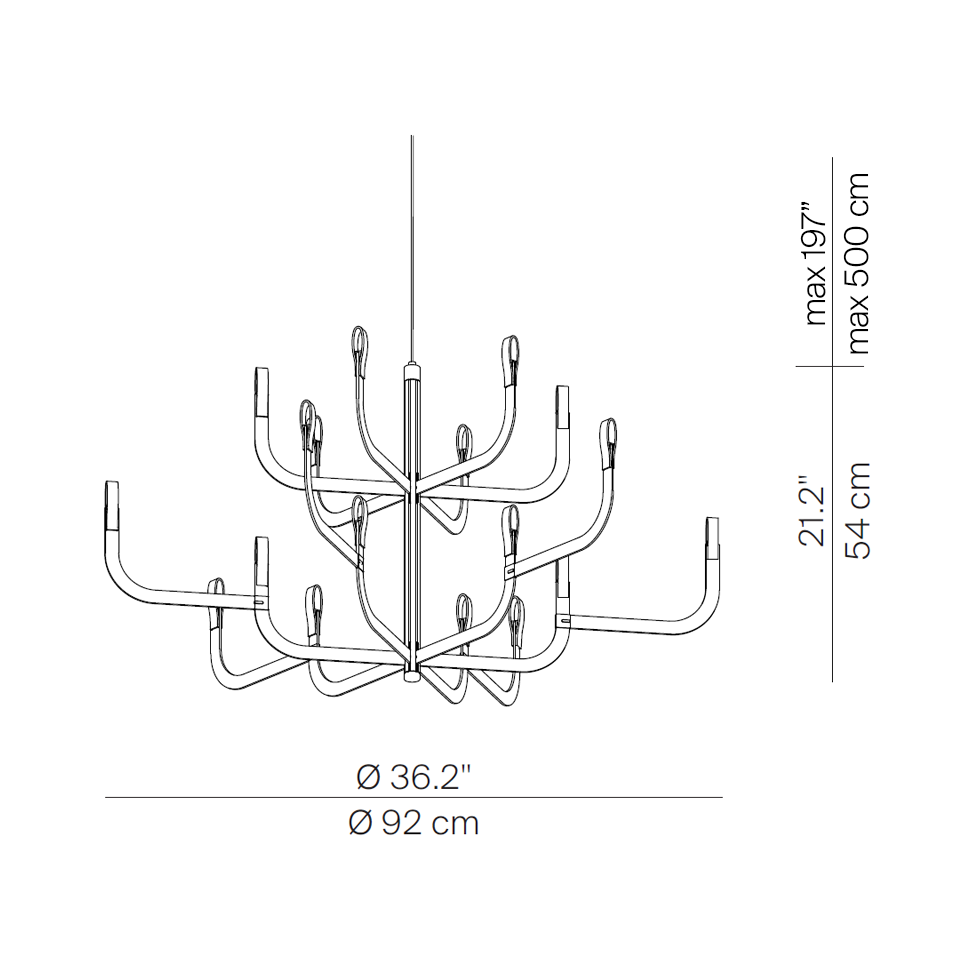

A09-C

J-us C configuration

A09-C

J-us C configuration

Main specifications

| Typology | Suspension | ||

|---|---|---|---|

| Application | Indoor | ||

| Material |

|

||

| Finishes |

|

||

| Dimensions (mm) | H body 540, cable max 5000, L 920 | ||

| Light Source | LED module 21W, 2700K | ||

| Insulation Class | I |

A09-E

J-us E configuration

A09-E

J-us E configuration

Main specifications

| Typology | Suspension | ||

|---|---|---|---|

| Application | Indoor | ||

| Material |

|

||

| Finishes |

|

||

| Dimensions (mm) | H body 540, cable max 5000, D ø 490 | ||

| Light Source | LED module 33W, 2700K | ||

| Insulation Class | I |

A09-G

J-us G configuration

A09-G

J-us G configuration

Main specifications

| Typology | Suspension | ||

|---|---|---|---|

| Application | Indoor | ||

| Material |

|

||

| Finishes |

|

||

| Dimensions (mm) | H body 540, cable max 5000, D ø 920 | ||

| Light Source | LED module 57W, 2700K | ||

| Insulation Class | I |