Floor

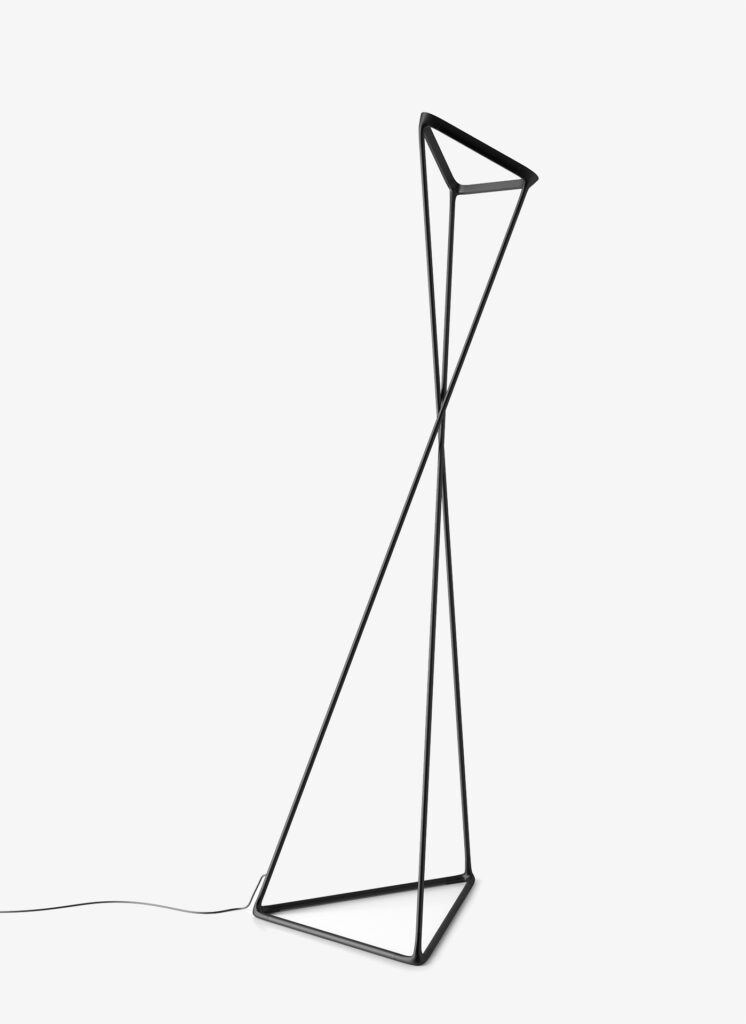

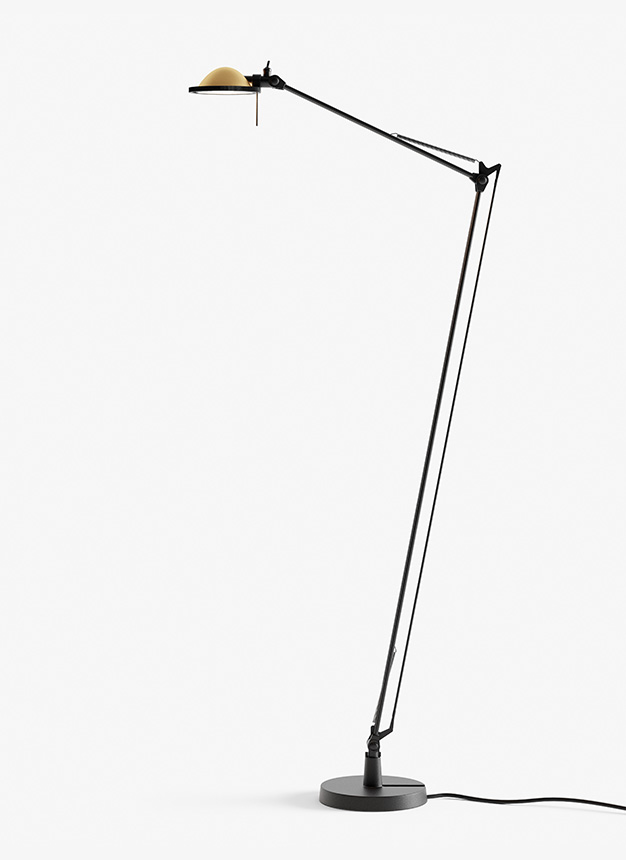

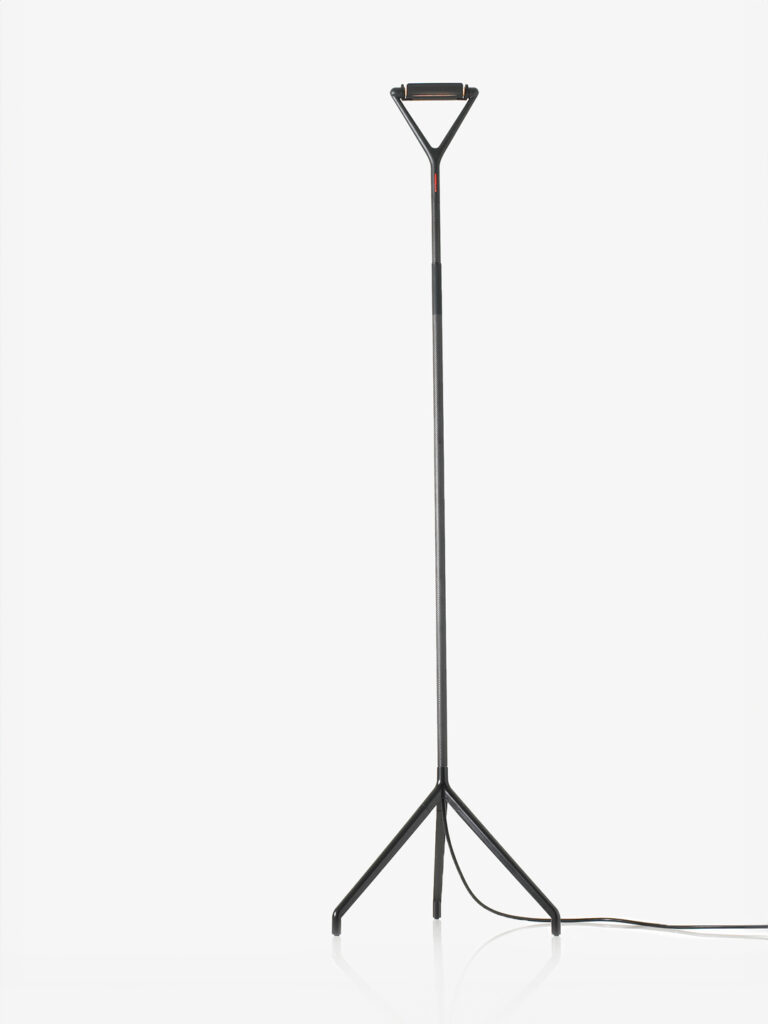

Luceplan floor lamps combine functionality and elegance to create modern products with high lighting performance.

Thanks to a variety of finishes and designs, they adapt to different rooms in the home, meeting different needs.

Looking for inspiration?

We offer solutions for every space, whether public or private. Discover our references and get inspired

Browse applications

Discover our collections

Download our catalogue and discover the collections

Download